In the automation equipment, there is such a dddhhhlow-key but powerfuldddhhh existence - Centrifugal Feeder. Sanitary Centrifugal Feeder can not only load materials at high speed and sort accurately, but also make a bunch of messy parts line up obediently and perfectly connect to the automated production line. Does it sound a bit magical? In fact, the principle of Sanitary Centrifugal Feeder is much simpler than you think.

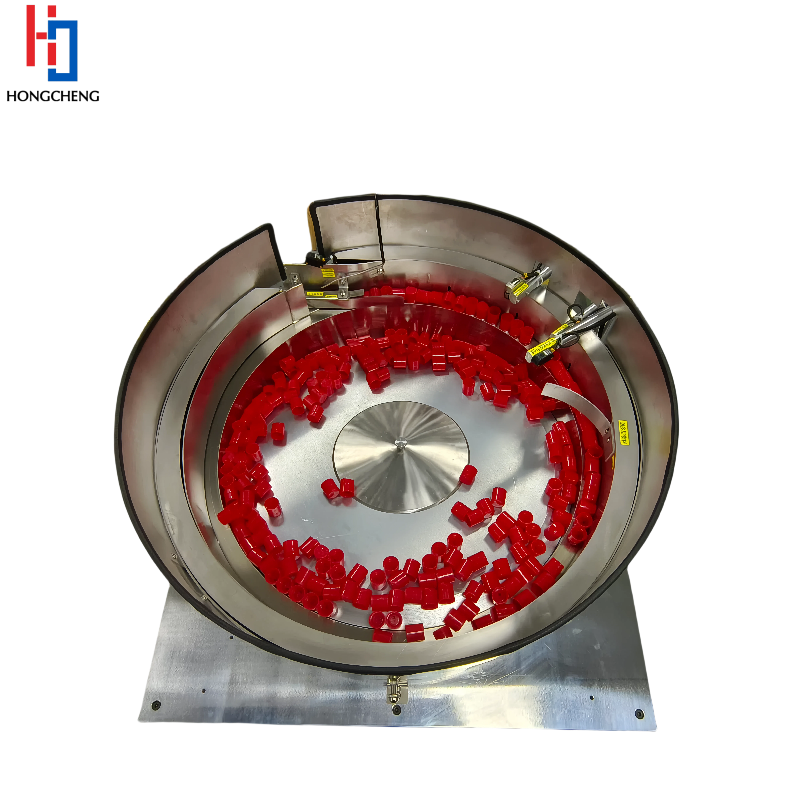

Centrifugal Feeder is a device that relies on rotational force to neatly arrange and output scattered parts in a directional manner. Centrifugal Feeder is like a large turntable that rotates rapidly, dddhhhthrowingdddhhh parts from the center to the edge of the track. In this process, the position screening and orientation unification are completed, and then output to the next station through the track. The whole set of movements is clean and neat, without any delay, and the sense of rhythm is comparable to that of a dancer.

Sanitary Centrifugal Feeder is very popular in industries such as cosmetic bottle caps, medical straws, food packaging caps, and small electrical accessories. Especially in scenes with high speed requirements, regular part shapes, and small sizes, the performance of the Sanitary Grade Centrifugal Feeders can be said to be the best in the field. Talking about this, if you are doing factory automation upgrades, or have needs for parts loading, then you must know Sanitary Centrifugal Feeder developed and produced by our hongcheng!

Centrifugal Feeder produced by Hongcheng has a compact structure and stable operation, and is designed for high-speed precision sorting. It has a wide range of adaptability, from plastic covers to hardware, to special customized workpieces, all of which can be accurately processed. Sanitary Grade Centrifugal Feeders supports customized design, and our engineering team can tailor a complete solution according to your part material, size, and production capacity requirements. It is easy to use and easy to change production and adjust, whether you are a large factory or a small workshop, you can easily get started.

In order to ensure the quality of the equipment, our production workshop is equipped with high-precision CNC machining centers, automatic welding lines and test stations. Each Sanitary Centrifugal Feeder shipped from the factory has undergone multiple performance tests and debugging to ensure that it will be a little helper for stable loading after it arrives in your workshop.

We also pay special attention to the selection of Sanitary Grade Centrifugal Feeders's dddhhhsilent processingdddhhh and dddhhhwear-resistant materialsdddhhh. Because we know that in modern factories, production efficiency and work comfort are equally important. So our Sanitary Centrifugal Feeder not only runs fast, but also dddhhhlight sounddddhhh, which greatly reduces the noise burden on site and improves the overall working environment.

At present, we have provided feeding systems for multiple automation projects, including orders from overseas customers. With reliable equipment performance and thoughtful technical support, our Sanitary Grade Centrifugal Feeders has received a lot of praise.

If you are also worried about dddhhhhow to quickly deliver these parts to the next stationdddhhh, then try our Sanitary Grade Centrifugal Feeders. Its rhythm, accuracy and flexibility may be the key step in your automation upgrade. Need a prototype demonstration? Feel free to contact us!