Hongcheng Welcomes European Delegation for In-Depth OEM Vibratory Feeder Facility Tour

Good day from the Hongcheng team! We are always delighted to welcome partners from around the world and share our commitment to precision engineering and collaborative innovation. Recently, we had the honor of hosting a delegation of engineers and project managers from a renowned European industrial group at our main production facility.

Their visit—focused on evaluating future cooperation on custom vibratory feeder solutions—offered a valuable opportunity for open technical exchange and allowed us to demonstrate our full capabilities as an experienced OEM vibratory feeder manufacturer, specializing in vibratory feeders, centrifugal feeders, and custom aluminum feeder bowls.

Strengthening International Cooperation in Automation

The visit highlighted Hongcheng’s active engagement in the global automation market, particularly within Europe’s highly demanding industrial sectors. The delegation participated in a comprehensive facility tour designed to present every stage of our one-stop production system, including concept development, engineering design, CNC machining, assembly, testing, and after-sales service.

Deep Dive Into Custom Engineering & Precision Manufacturing

The tour began in our R&D and Technical Proposal Center, where our engineering team demonstrated how customer requirements—material characteristics, feed rate targets, factory layout constraints, and integration requirements—are converted into practical and customized vibratory feeder solutions.

Discussions covered:

Drive unit selection (electromagnetic vs. motor-driven)

Feeder tray design, including lightweight aluminum bowls and food-grade applications

Control system compatibility for different automation environments

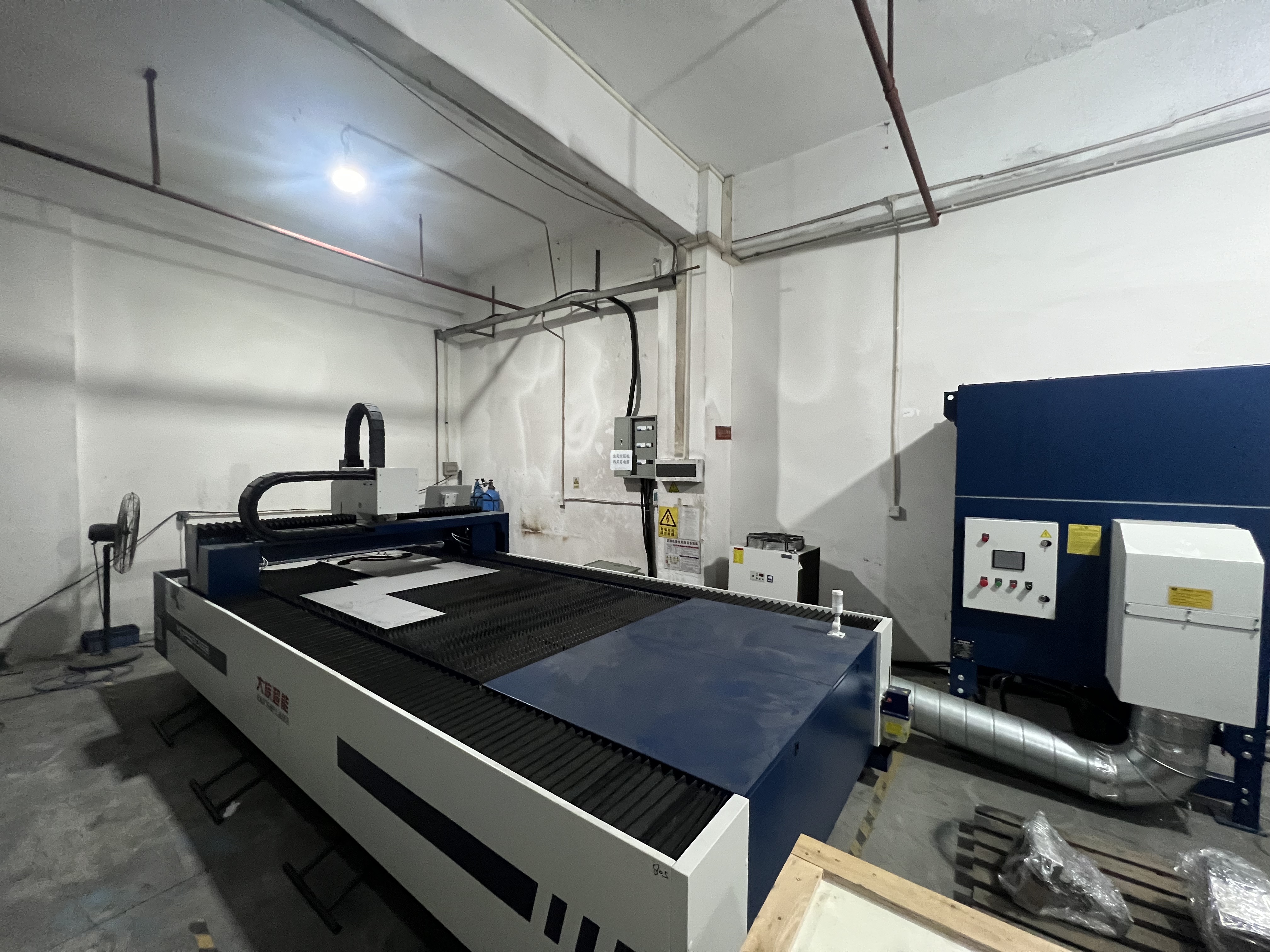

On the manufacturing floor, the delegation observed our advanced CNC machining centers producing high-precision components essential for long-term feeder stability. The aluminum feeder bowl machining area gained particular attention, showcasing our ability to fabricate corrosion-resistant, lightweight, and fully customized trays.

In the assembly zone, visitors watched our technicians fine-tune and dynamically balance each feeder to ensure stable amplitude and consistent feeding performance—key indicators of quality in high-performance automation systems.

Showcasing Integrated System Capabilities

To demonstrate our role as a complete automation solutions provider, we also showcased equipment often integrated into feeding lines, including our centrifugal feeders used for high-speed orientation and sorting. The synergy between vibratory feeders and centrifugal feeders illustrated our ability to design holistic, system-level material handling solutions, not just standalone equipment.

Commitment to Quality Assurance & Long-Term Partnership

A critical part of the visit took place in our Quality Control Laboratory. The delegation reviewed our rigorous QA framework, including:

Material certification for stainless steel and aluminum alloys

Laser alignment and amplitude testing

Full-load endurance testing for long-term operation

Compliance with CE and other international standards

This level of manufacturing transparency reinforces the trust required for long-term OEM cooperation, especially for customers with strict European compliance requirements.

Building a Foundation for Future Cooperation

Although the visit did not result in an immediate contract—which is common for large-scale OEM projects with longer decision cycles—the exchange was highly meaningful. It confirmed that Hongcheng’s technical strength, transparent manufacturing processes, and customer-centric approach strongly resonate with professional clients across Europe.

We sincerely appreciate the delegation’s time and insights. As always, Hongcheng remains dedicated to being a trusted global partner for custom vibratory feeder systems, offering dependable quality, innovative engineering, and seamless system integration.

We welcome partners worldwide to visit our facility and experience firsthand the craftsmanship behind our vibratory feeders, centrifugal feeders, straight feeders, and precision aluminum bowls.

Ready to explore how Hongcheng’s OEM expertise can support your next automation project?

Contact our team today to schedule your personalized facility tour or technical consultation.